ODE R-Flex Sheet

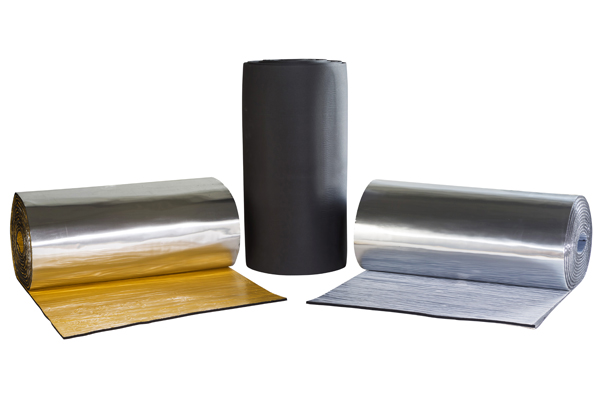

ODE R-FLEX Sheet is manufactured in to three groups, DIAMOND, PRM and STD with various types of facing.

PROPERTIES:

- Elastomeric rubber foam used for insulating chilled water and cooling system installations.

- It offers ideal solutions for heating, cooling installations and for ventilation systems.

- It offers maximum savings with its low thermal conductivity.

- It does not transmit water vapor thanks to its high µ (water vapor diffusion resistance factor) value.

- It is not affected by mold and microorganisms.

LAMINATED PRODUCTS:

ODE R-FLEX’s laminated products are;

R-FLEX ALUGLASS (Aluminum Glass Fabric)

R-FLEX AL-CLAD (Aluminium Cladding)

R-FLEX ALU (Aluminium Foil Facing)

R-FLEX METALIZED (Metalized Facing)

R-FLEX SA (Self Adhesive)

ODE R-FLEX ALUGLASS Sheet

- The top surface of the product is coated with Aluglass (aluminum glass fabric)

- It has 95 g / m glass cloth material.

- It has high fire and UV resistance thanks to its glass cloth surface.

- Complete sealing and minimal workmanship mistakes.

- It maintains its elasticity property at low and high temperatures and does not deteriorate its lamination.

- High pressure resistance .

ODE R-FLEX AL- CLAD Sheet

- Developed as an alternative to 0.8 – 1 mm aluminum metal lamination. It has a high-strength aluminum foil coating as the top coat.

- Self-adhesive on one side, if desired. Full and excellent adhesion to the surface of the duct with reinforced adhesive.

- Applicable to the outdoor systems with UV resistant external lamination.*

- Advantages of fast application, minimum labour and waste (2-3%)

- Optimal sizes (1000-1200mm) and various thickness for duct installation.

- Increase in the water vapour diffusion resistance of the product.

- Complete sealing and minimal workmanship mistakes.

- Preservation of the form against mechanical impacts

ODE R-FLEX ALU Sheet

- It is covered with aluminum facing. Is faced with durable laminated aluminum and polyester.

- Can be manufactured with a self-adhesive side upon request. Thanks to its reinforced adhesive, it ensured full and excellent adhesion to the duct surface.

- Maintains its form despite mechanical shocks.

- The aluminum foil facing visually complements the duct on which the product is applied.

- Raises the product's water vapor diffusion resistance.

- It provides full impermeability and eliminates errors in workmanship.

- It is manufactured in sizes that are best suited for duct insulation (1000-1200 mm) and in various thicknesses.

- It helps reduce vibration at duct connections thanks to its flexible structure.

- Saves on application time and labor.

- Reduces wastage to 2-3%.

ODE R-FLEX METALIZED Sheet

- Elastomeric rubber foam sheet with Metalized PET film as their final facing layer.

- Has high strength and surface hardness by virtue of its characteristics.

- Increases the product’s water vapour diffusion resistance.

- Raises UV resistance.

- It is manufactured in sizes that are best suited for duct insulation

(1000-1200 mm) and in various thicknesses. - It is easily applied.

- Saves on labour.

- It is cost friendly.

ODE R-FLEX SA Sheet

Self-adhesive elastomeric rubber sheets.

- Two types of protective facing is used on the adhesive surface.

SA with kraft paper

SA with HDPE film

- Adhesive surfaces are manufactured with and without a "mesh". The use of product with mesh is recommended for ducts with large cross-sections.

- It physically adheres to the duct thanks to its self-adhesive surface.

- Does not carry the risks that come with chemical adhesion.

- It provides full impermeability.

- The same quality of adhesion is achieved in all surfaces.

- Facilitates application on the ground.

- Reduces labor time by 40%.

| Name of Product |

λ (Thermal Conductivity) W/m.k |

μ (Water Vapor Diffusion Resistance Factor) |

Fire Class (EN 13501-1) |

| R-FLEX DIAMOND Sheet | 0.032(-20ºC) | 11000 | B-s3-d0 |

| 0.034(0ºC) | |||

| 0.036(+20ºC) |

| Name of Product |

λ (Thermal Conductivity) W/m.k |

μ (Water Vapor Diffusion Resistance Factor) |

Fire Class (EN 13501-1) |

| R-FLEX PRM Sheet | 0.032(-20ºC) | 7000 | B-s3-d0 |

| 0.034(0ºC) | |||

| 0.036(+20ºC) |

| Name of Product |

λ (Thermal Conductivity) W/m.k |

μ (Water Vapor Diffusion Resistance Factor) |

Fire Class (EN 13501-1) |

| R-FLEX STD Sheet | 0.034(-20ºC) | 5000 | B-s3-d0 |

| 0.036(0ºC) | |||

| 0.038(+20ºC) |

| Width | Thickness (mm) | |||||||||

| 6 | 9 | 10 | 13 | 19 | 25 | 32 | 40 | 50 | 60 | |

| 1000 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 1200 | √ | √ | √ | √ | √ | √ | √ | √ | √ | - |

| 1500 | - | - | - | √ | √ | √ | √ | - | - | - |

ODE KONFiX (ODE R-FLEX ADHESIVE)

Synthetic rubber based super-strong adhesive used in ODE R-flex applications. Prevents convection currents at joints, facilitates easy and fast installation. Surfaces to which the product shall be applied should not be greasy or dusty, and ODE Konfix should be applied by using a roll, brush, or spray gun equally on both surfaces, and adhesion should be ensured under constant pressure. The drying period varies between 10 seconds and 4 minutes, and the time required for complete adhesion is 24 hours.

| Adhesives | Quantity (kg) |

| ODE KONFIX 14/1 | 14 |

| ODE KONFIX 3/1 | 3 |

| ODE EKO KONFIX 14/1 | 14 |

| ODE EKO KONFIX 3/1 | 3 |

Soğuk ve ılık hatlarda büyük çaplı boru ve havalandırma kanallarının yalıtımında kullanılır.

UYGULAMA ESASLARI

KLİMA KANATLARININ YALITIMI

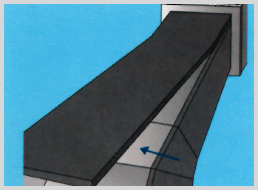

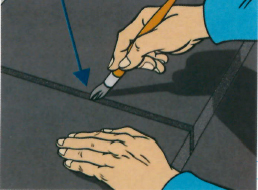

| 1. Carefully clean the surface that is to be insulated. Nothing that can hinder adhesion should be left on the surface. Measure the duct surface that is to be insulated, and cut the appropriate size of ODE R-Flex Board from the roll. |  |

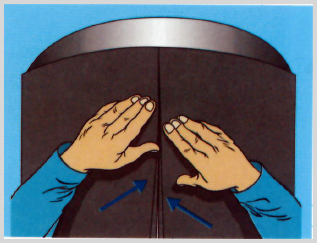

| 2. Apply ODE R-FLEX Adhesive on the surface of the ODE R-FLEX that is to be attached to the duct and on the duct surface. To obtain good results, first cover the lower surface of the duct, then the side surfaces, and finally the top surface. |  |

| 3. Attach the sides together using ODE R-FLEX Adhesive. |  |

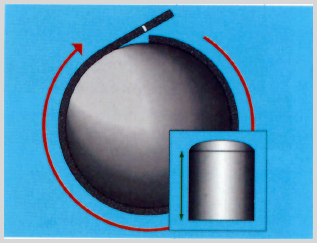

TANKLARIN YALITIMI

| 1. Carefully clean the entire surface before beginning insulation. Measure the height of the tank and its circumference with the ODE R-FLEX Board. |

|

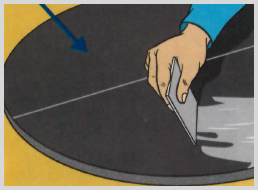

| 2. Transfer the measurements onto an ODE R-Flex Board and cut. Apply ODE R-Flex Adhesive to the entire surface of the ODE R-Flex Board using a spatula, and to the tank surface using a brush. Apply adhesive to the edges of the board and attach the board to the tank. Attach the sides together. |

|

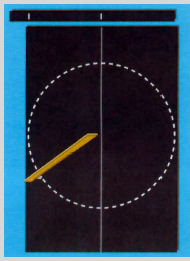

| 3. Measure against the ODE R-FLEX Board to insulate the convex area. |  |

| 4. Calculate the diameter and draw the circle that will cover the convex area. Cut the circle out carefully at the marked places. |  |

| 5. Apply ODE R-Flex Adhesive to the piece you have cut out and to the convex surface of the tank that is to be covered. |  |

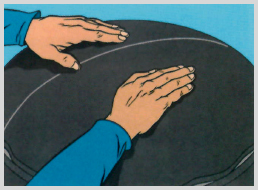

| 6. Place the piece on the area and press down to prevent it from sliding toward the outer edge. |

|

| 7. When the piece has adhered to the tank surface, apply ODE R-Flex adhesive on the edges all along the circumference. After the adhesive is dry, attach the piece to the ODE R-FLEX Board covering the man body of the tank by firmly pressing the edges together. |