ODE Starflex Board

The ODE STARFLEX Board Group is manufactured in the thermal conductivity range of λ = 0.031-0.037 W/(m.K).

AREAS OF USE

- Between rafters,

- Cavity walls,

- Partition walls,

- Suspended floors,

- Suspended ceilings,

- Ventilated facade,

ADVANTAGES

- Its classification as a "Class A1 Non-Combustible" (EN 13501-1) material is a very significant advantage for fire safety.

- It does not undergo any dimensional changes when exposed to varying temperatures and humidity.

- It does not degrade, decompose, corrode or become moldy in time.

- It is indestructible by insects and microorganisms.

- Thanks to its natural content, it does not degrade and is user friendly.

- It is EUCEB certified as not harmful to human health;

- With its EPD Document, it furnishes additional scores for buildings wishing to obtain LEED, BREEAM, DGNB, etc. certification.

|

NAME OF PRODUCT |

ODE STARFLEX |

||||||

|

Property |

Unit |

ODE STARFLEX BOARD GROUP |

|||||

|

Type |

_ |

STARFLEX 037 |

STARFLEX 035 |

STARFLEX 032 |

STARFLEX 031 |

||

|

Thickness |

mm |

50-220 |

50-220 | 25-180 | 20-100 | ||

|

Fire Response |

Euro Class |

A1 |

|||||

|

Thermal Conductivity (λ) (10°C) |

W/ (m.K) |

0.037 |

0.035 |

0.032 |

0.031 |

||

|

Thermal Resistance (R) |

(m.2K)/W |

1.35-5.90 | 1.40-6.25 | 0.75-5.60 | 0.65-3.20 | ||

|

Water Vapor Permeability (μ) |

_ |

1.1 |

|||||

|

Maximum Service Temperature |

°C |

250 |

|||||

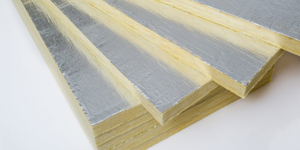

LAMINATION TYPES

ODE Starflex board can be used with various types of facing.

| YGT | Yellow Glass Tissue |  |

| BGT | Black Glass Tissue |  |

| FSK | Foil Scrim Kraft |  |

| CLASS 0 | Class 0 Alu |  |

| WGF | Woven Glass Fabric |  |